CNC Waterjet Cutting:

A

water jet cutter, also known as a

water jet or

waterjet, is an industrial tool capable of cutting a wide variety of materials using a very high-pressure jet of water, or a mixture of water and an abrasive substance. The term

abrasivejet refers specifically to the use of a mixture of water and abrasive to cut hard materials such as metal or granite, while the terms

pure waterjet and

water-only cutting refer to waterjet cutting without the use of added abrasives, often used for softer materials such as wood or rubber.

Waterjet cutting is often used during fabrication of machine parts.

It is the preferred method when the materials being cut are sensitive to

the high temperatures generated by other methods. Waterjet cutting is

used in various industries including mining and aerospace for cutting, shaping, and reaming.

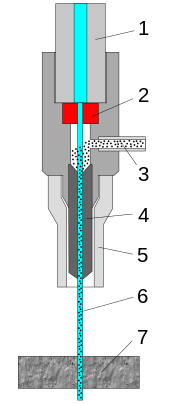

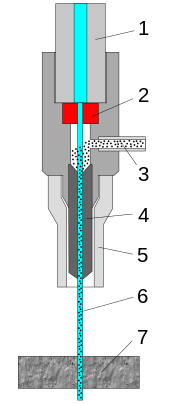

1.High-Pressure Water Inlet. 2: Jewel (Ruby or Diamond). 3: Abrasive

(Garnet). 4: Mixing Tube. 5: Guard. 6: Cutting Water Jet. 7: Cut Material

1.High-Pressure Water Inlet. 2: Jewel (Ruby or Diamond). 3: Abrasive

(Garnet). 4: Mixing Tube. 5: Guard. 6: Cutting Water Jet. 7: Cut Material

|

| Water jet Cutter Tool |

|

|

|

|

|

|

| |

|

|

|

|

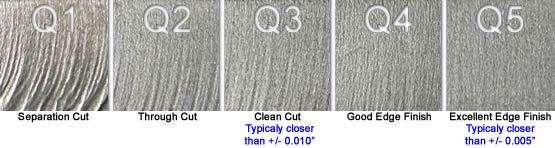

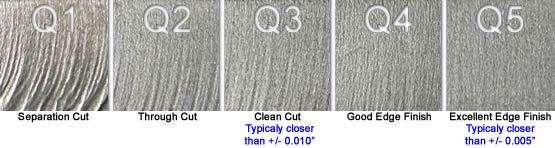

Edge quality

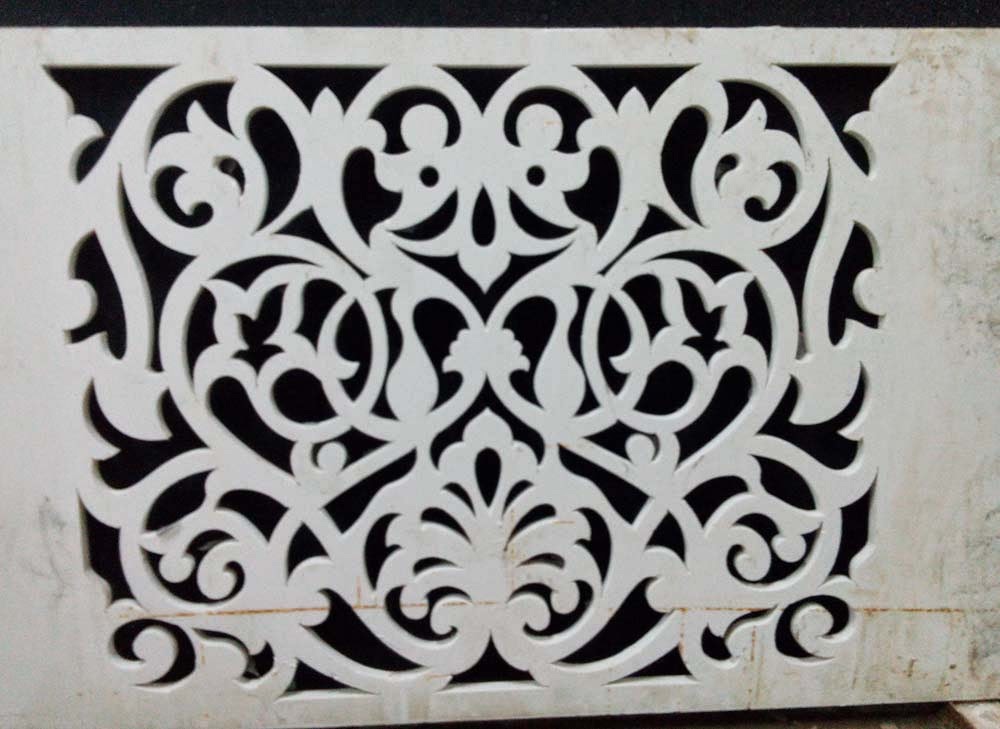

Decorative Designs Gallery made by Water jet Cutting:

Decorative Designs Gallery made by Water jet Cutting:

Home Decoration, Wall Decoration, Stone Decoration,Interior Decoration Pictures, Room Decoration

Waterjet cutting Raw Materials:

1.Engineering Part Work

| Job Shops, |

Matching precision parts |

Medical Applications |

MS/SS | | | | |

Precision gears

and sprockets |

Thick precision parts |

Thin precision parts |

|

2.Metal: Aluminum,copper,Hardened Tool Steel,Stainless steel,Steel,Titanium

3.Ceramics:

Ceramics are made by heating up minerals to a high temperature.

Traditionally, ceramics have been made from clay, but modern ceramics

are made from substances such as alumina and from synthetic materials.

Ceramics are electrical insulators and resist corrosion.

4. Composites:

Composites are similar to fiberglass and consist of layers of material.

Abrasivejets can machine composites without leaving a burr or shredding

the layers of material and, while maintaining a better edge quality.

5. Rubber:

Water-only waterjet nozzles cut rubber faster and cleaner, though some

very hard rubbers may require abrasive. Water-only cutting wastes little

material, is quieter and increases the nozzle life. Water-only cutting

also proceeds very quickly at speeds of 100 inches per minute or faster.

6.Exotic Alloys:

It's hard to beat a simple jigsaw, but some precision abrasivejet

systems are being used to cut wood, typically for special intricate

shapes and only after delivering a return on investment via metal parts

production.

7. Stone:

stone is difficult to machine conventionally, but very intricate shapes can be cut with a precision abrasivejet using low-pressure pierce capability.

8.Glass:

Glass is a unique substance that was traditionally been difficult to

machine. Although it has a great deal of structural strength, even small

scratches on the surface can lead to breaking and shearing.

9.Wood:

It's

hard to beat a simple jigsaw, but some precision abrasivejet systems

are being used to cut wood, typically for special intricate shapes and

only after delivering a return on investment via metal parts production.

For More Information:

Visit: www.gkindus.com

Contact Person: Mr.Gokul Krishnan

Phone: 91-99442 67889 , 91- 98437-31711

Address: GK Industries

18/B, Rajaji nagar, Trichy road Singanallur,

Coimbatore,

Tamil Nadu -641005, India

1.High-Pressure Water Inlet. 2: Jewel (Ruby or Diamond). 3: Abrasive

(Garnet). 4: Mixing Tube. 5: Guard. 6: Cutting Water Jet. 7: Cut Material

1.High-Pressure Water Inlet. 2: Jewel (Ruby or Diamond). 3: Abrasive

(Garnet). 4: Mixing Tube. 5: Guard. 6: Cutting Water Jet. 7: Cut Material