If you appear in to your day by day life, then you can acquire to recognize

the fact that the water jet has main

role in the protection of your sewage-system - be it at house, or any other bigger

place. Well, now if you need to acquire the water jet cutting services completed

in the good way, then you must rely in the ideal company thus that you don’t

have any cause to repent later on. You just want to do is, to recognize regarding

the specifications of GK Industries Company and its capability in the water jet

cutting feature. Read out this post, to know why should choose water jet cutting services Coimbatore

Why should find water jet cutting services?

Best benefits

The primary benefit that you can obtain from this concern in this field

is, their working method is very eco-friendly and this is the cause since to

why you can love to get assist from this business. The maximum temp of nozzle which

is utilized in turn to formulate the cutting is incredible around 50°C and yet

less sometimes. As well as, no-hazardous items are formed as an outcome thus

that is certainly a big thing.

Other privileges

The metal cutting services offers with high-thickness cutting that refers

that you can slice based on your appropriateness and sure there will be

no-problems regarding that. It is totally incredible that the water jet cutting

services can cut the stainless steel with thickness of about 170-mm as well as

it can cut 250-mm aluminium and finally, 300-mm Titanium and thus it is not a subject

of joke.

Other prospects to be considered

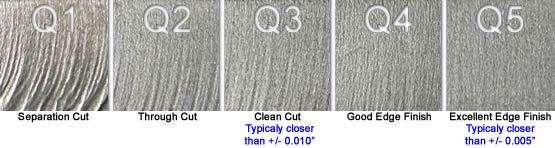

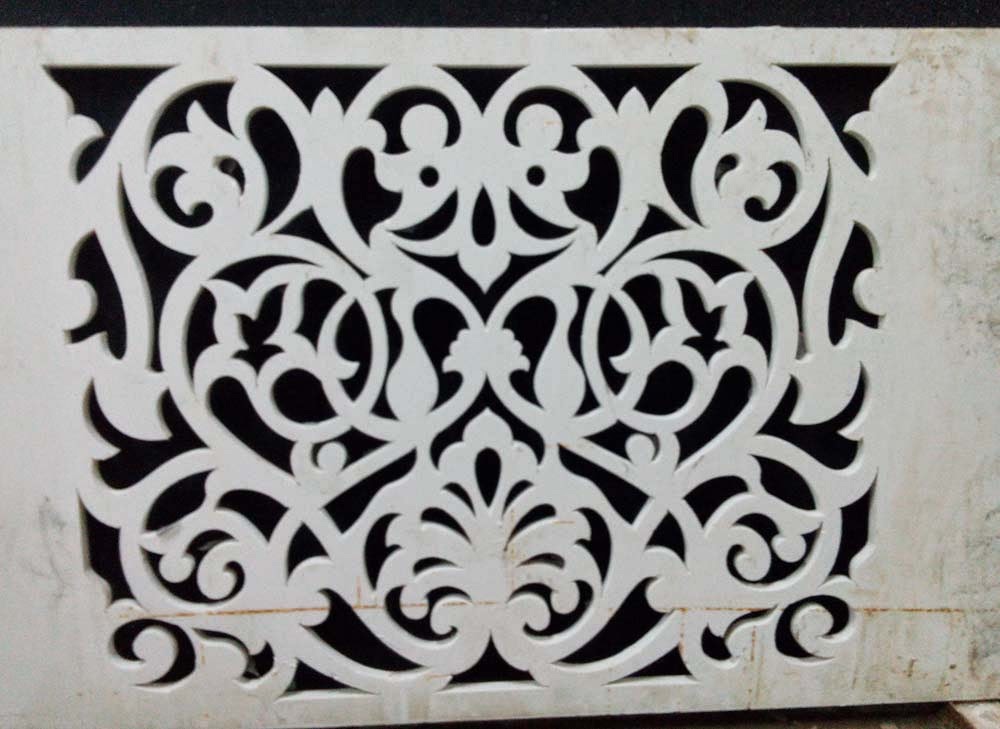

The CNC water jet cutting services in Coimbatore provides excellent

outcome. It is good to choose waterjet cutting tool for cutting any type of

parts to make precise output. This refers that the device that is there in the concern

can really cut any type of 2D shape- it doesn’t matter what the objects is. Another

ideal aspect is the quality of cutting is high-edge and the softness is just amazing.

The raw objects are saved to lots of extent as because of fact that the slice

is done in smooth manner thus that there is no-wastage of materials.

Now all you need to do is, you have to end-up with best company and of

course, you can look at GK Industries for best water jet cutting services.

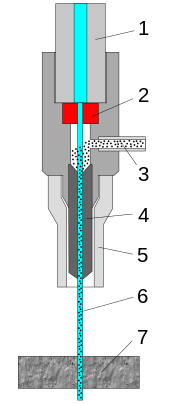

1.High-Pressure Water Inlet. 2: Jewel (Ruby or Diamond). 3: Abrasive

(Garnet). 4: Mixing Tube. 5: Guard. 6: Cutting Water Jet. 7: Cut Material

1.High-Pressure Water Inlet. 2: Jewel (Ruby or Diamond). 3: Abrasive

(Garnet). 4: Mixing Tube. 5: Guard. 6: Cutting Water Jet. 7: Cut Material